-

1. Introduction

The continuous synchronization of the basic flow of the companies and the profitability of this flow is and will remain an eternal challenge of the manufacturing company to ensure the eternal prosperity in a global market. Even if different approaches are used to achieve lead time reduction […]

-

Some managers and practitioners are wrong when they want to improve their productivity to increase production. The level of productivity does not depend on the volume of production. Production and productivity are completely different subjects. Productivity does not improve only by increasing production and vice versa.

[…]

-

To be honest, many of those who make improvements just review what has already been designed.

Often real-time business managers say:we need an improvement in price competitiveness on the basis of a continuous and flexible reduction of unit costs;

we would like to reform the current profit structure so we can inte […]

-

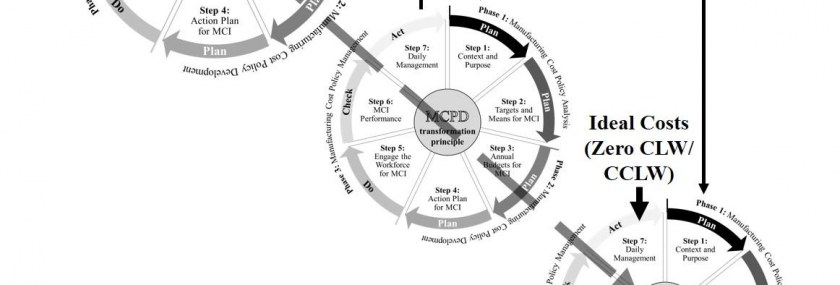

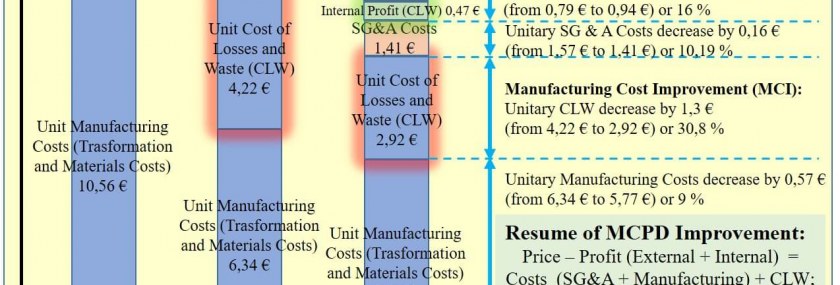

The basic goal of MCPD thinking is to ensure a sustainable competitive supremacy through cost-competitiveness improvement to achieve real structural profit reform based on productivity reform.

At the beginning of the MCPD projects, managers and practitioners are concerned about:concomitant reconciliation between the […]

-

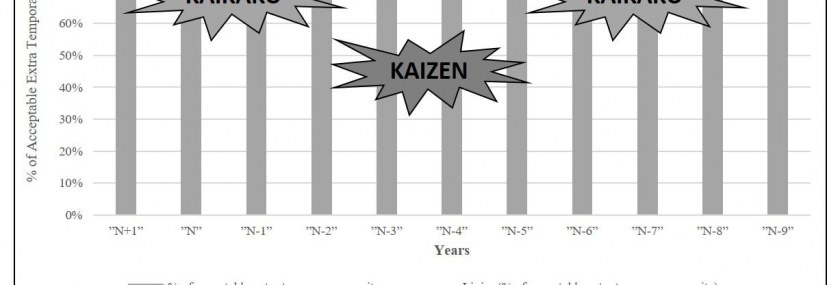

Often, one of the first questions that I ask top managers is about the current and future production capacity needed in connection with the vision and mission of productivity.

Successful planning and implementation of strategic Kaizen and Kaikaku for cost improvement requires answers to questions such as:What is the s […]

-

In an economically slow growth environment, the continuous improvement of productivity is even more important for maintaining profits growth. Unfortunately, when it comes to achieving the annual improvement targets, most companies start too late, run too slow or never develop a consistent plan.

Planning and detailed implementation of the […] -

As it is known, companies want to make improvements to ensure a continuous transformation process for the synchronization with market demands (shareholders, customers, suppliers and competitors).

Nonetheless, many barriers in companies often encounter this harmonious transformation to market demands, especially at the level of: policy dep […] -

Industry 4.0: best practice, the role of man and the future of productivity in factories

Increasingly, it is believed that Industry 4.0 will significantly transform the design, manufacture, operation, services and manufacturing systems as a whole. As some of you already know, Industry 4.0 has 9 pillars: (1) Big data and analytics; (2) Aut […] -

As is well known, productivity is also closely linked to the operator, equipment, and/ or line time cycle. Over time, significant time cycle variations (standard cycle time vs. real cycle time) result in amplification of the non-synchronization of the flow precesses (work centers) and, implicitly, a disturbance to the standardization of t […]

English

English Romana

Romana