-

Companies are aware that production planning has to take into account each type of set-up time.

Practitioners admit that they need set-up time standardization (SOP for set-up) for: (1) increasing flexibility and (2) continually improving set-up time. Sometimes, it is difficult for them to convince managers that for this […] -

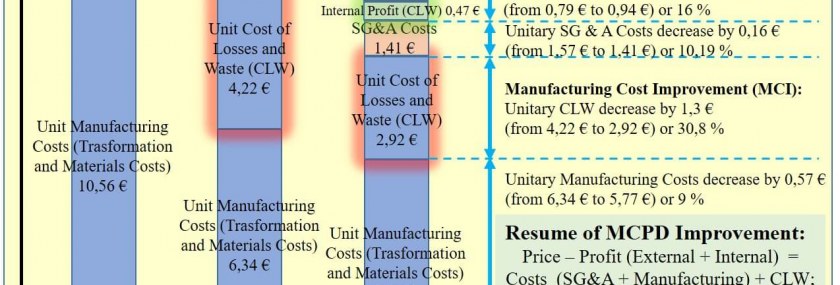

After the various improvements have been implemented, the total value of the cost improvement often seems to be high, but it does not seem to bring visible improvements in business results (especially competitive price, volume and profit).

Having spent a lot of time in several companies lately, the current challenges are […] -

Indirect materials have amazing costs in most companies. However, often their standardization and improvement is not a continuous focus for companies (with visible results).

Large variations between system and factual data are often encountered, increasing and generating large and continuous discussions.

Often those invo […] -

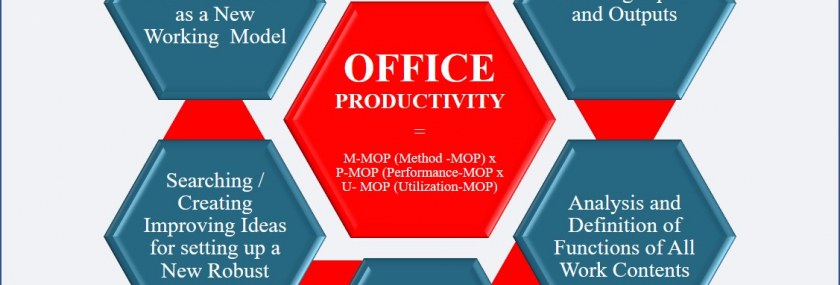

Productivity is the task of everyone – not just those directly involved in operations. Increasing the productivity of administrative functions is absolutely necessary.

Often, to increase productivity in offices, the current work method is intensified – a method that is often inadequate. This intensification o […] -

The fundamental task of any team of top managers is to develop a clear idea about the direction in which the company should go in the coming years. To do this, they need to clearly understand who they are and what their position is in the company and use this understanding to identify what are the main issues and how the […]

-

In every manufacturing company there is a flow of container transport to the work places (tour and return). But often there are numerous losses & waste associated with delays and/ or non-compliant supplies of containers. The annual costs associated with these types of losses & waste, together with the annual lost […]

-

Although the 5S method is the basis of management, often the 5S concept simply remains a rather meaningless slogan in some companies.

It is often the case that after several years since the “completion of 5S implementation”, some managers still have questions like: “Why 5S to us?”.

Managers say th […] -

Even if all companies would like to be able to use all the resources they have to their fullest extent and to completely eliminate all losses & waste, often their actions are not part of a real culture of improvement.

Recently, I visited a few companies that highlighted equipment issues (especially breakdown and mino […] -

We invite you to the next session of the Controlling – Costing, Budgeting and Cost Reduction open traning that will take place on February 19-21, 2020, in Sibiu. This program is specifically designed to show top managers and professionals in Controlling the necessary individual and organizational adjustments for th […]

-

Should an equipment/line that has significant variations between the standard and the actual cycle time be declared in a breakdown state? (standard cycle time lower than actual cycle time).

Sometimes I have this discussion in factories. Do you have standard cycle time on equipment/line? Do you measure the differences bet […]

English

English Romana

Romana